تجهیزات تغذیه سنگ معدن

-

فیدر دیسک نوعی تجهیزات تغذیه ای با ظرفیت متوالی با استفاده گسترده است. این ماده می تواند به طور مساوی و متوالی مواد ر...

-

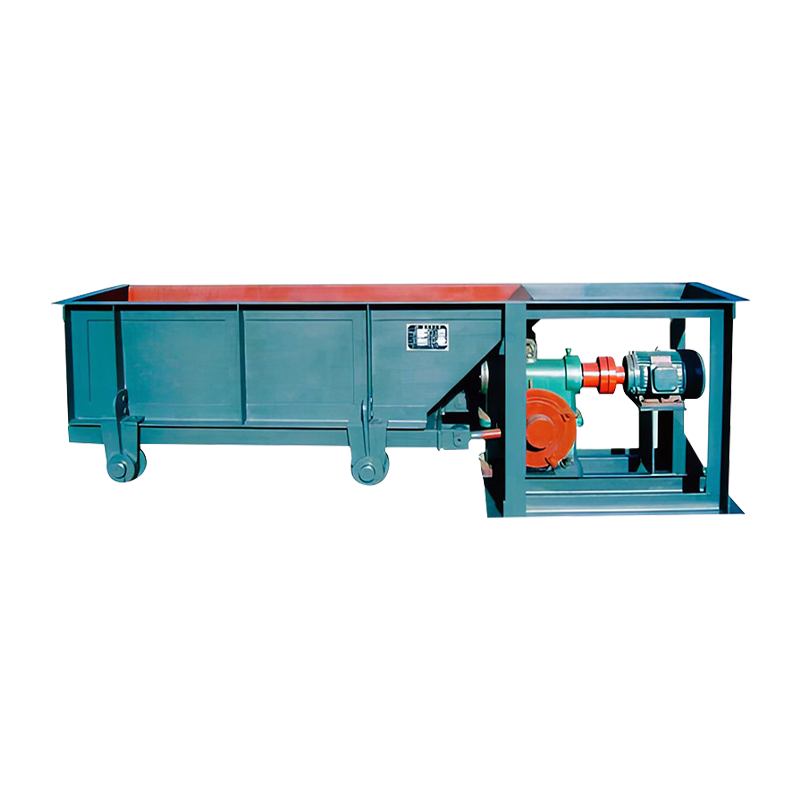

فیدرهای نوع کانال برای فرآوری مواد معدنی ، ذغال سنگ ، مواد شیمیایی و سایر بخش های صنعتی مناسب هستند. این مواد ذرات و ...

-

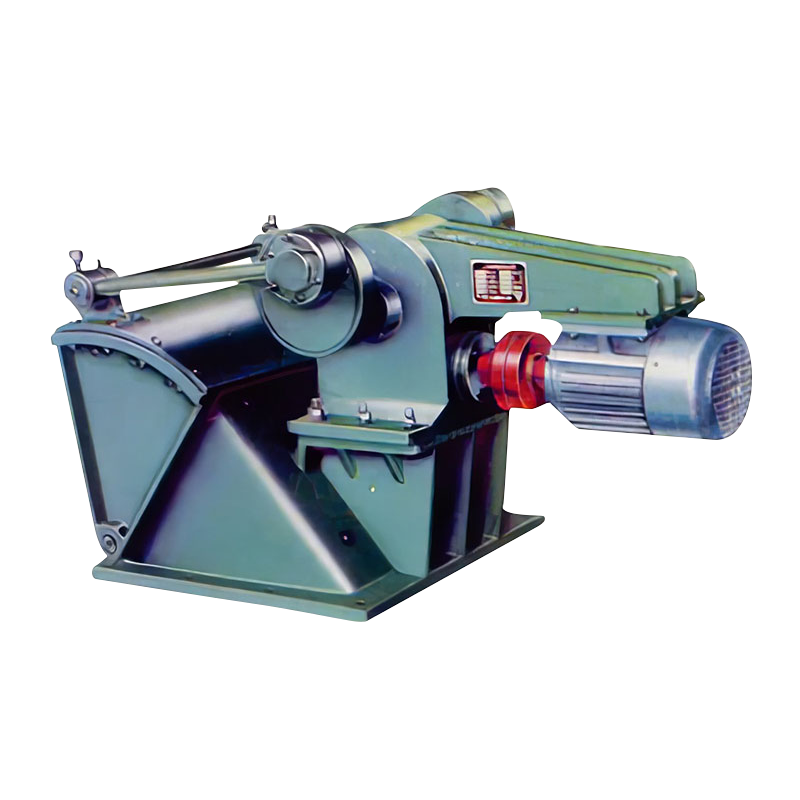

فیدرهای نوع نوسان برای فرآوری مواد معدنی ، ذغال سنگ ، مواد شیمیایی و سایر بخش های صنعتی مناسب هستند. این ماده ذرات را...

-

0+

0+تست و تولید تجهیزات

-

0تن

0تنتولید سالانه

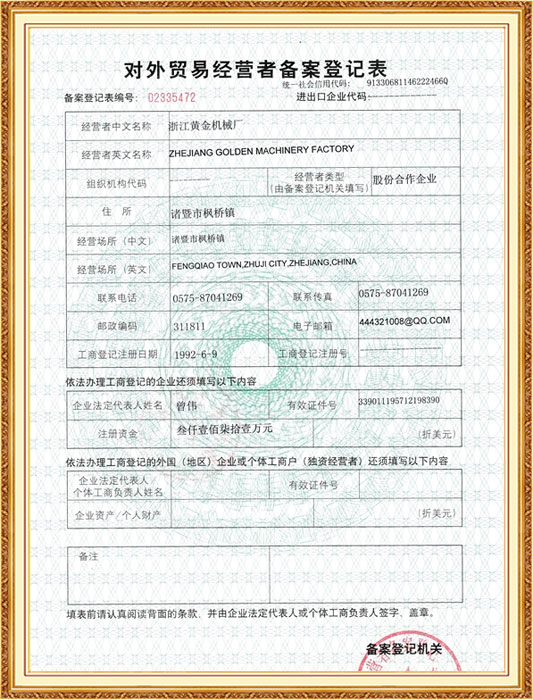

Zhejiang Golden Machinery Factory یک شرکت متوسط ملی و همچنین یک شرکت پیشرفته در استان ژجیانگ است. یک مرکز تحقیق و توسعه حرفه ای وجود دارد که محصول R & D و تولید را ادغام می کند. این شرکت حدود 200 تجهیزات مختلف آزمایش و تولید برای ساخت ماشین آلات و با تجربه غنی در کار نصب و اشکال زدایی دارد. در غیر این صورت ، کارخانه به طور دقیق از سیستم مدیریت کیفیت IS09001: 2008 و تولید سالانه سازه های فلزی کار فلزی بیش از 25000 تن است. ما همکاری فنی پایدار با آکادمی های صنعت شیمیایی متالورژی داریم. در ده ها سال در حال توسعه ، ما به تدریج اختلاط تجهیزات غنی سازی برای هیدرومتالورژی را بهبود می بخشیم. در حال حاضر ، تکنیک و تجهیزات هیدرومتالورژی ما هنوز در سطح داخلی است. به دلیل مفهوم نوآوری مداوم رهبری و تکنیک پیشرفته ، شرکت ما در حال حاضر به شرکت در چین تبدیل شده است که متعلق به فناوری ها و تجهیزات یکپارچه برای هیدرومتالورژی است.

محصولات اصلی این شرکت تجهیزات خرد کردن و آسیاب توپ ، مخلوط کردن مخزن و تجهیزات شناور ، تجهیزات غلظت و غربالگری ، تجهیزات آشفتگی و تجهیزات اختلاط در مقیاس بزرگ برای نمک دریاچه Potash است. این می تواند مجموعه کاملی از تجهیزات فنی اصلی و مجموعه های کاملی از مهندسی را برای معدن ، مصالح ساختمانی ، متالورژی ، فلز غیرمترقبه ، انرژی برقی ، صنایع شیمیایی ، حفاظت از محیط زیست و سایر صنایع اساسی فراهم کند. در داخل کشور ، قبلاً معدن غربی ، زیجینین ، کودهای پتاس سالت دریاچه ، طلای یوگوانگ و سرب ، پتاسیم با سرمایه گذاری دولتی ، نفیین ، جیانگشی کوپه ، فلزات تونگلی و سایر پروژه های کلیدی ملی را فراهم کرده است و با تجهیزات و خدمات فناوری. علاوه بر این ، محصولات نیز به آسیا ، آفریقا ، ایالات متحده ، استرالیا و سایر کشورها و مناطق فروخته می شوند.

"صداقت ، نوآوری ، کیفیت بالا و کارآیی ، کاربران راضی" فلسفه تجارت ما است. ما مایلیم محصولات و خدمات با کیفیت بالا را در اختیار مشتری خود قرار دهیم. ما با جدیت به کار خود ادامه خواهیم داد و امیدواریم با اخلاص ، توسعه مشترک شما همکاری کنیم و آینده ای شکوهمند را با هم ایجاد کنیم!

-

Admin 26 Jan 2026

نوع BF در مقابل ماشین شناور KYF/XCF: مقایسه فنی و استراتژی انتخاب

در صنعت فرآوری مواد معدنی مدرن، انتخاب مناسب دستگاه فلوتاسیون برای متعادل کردن نرخ بازیابی و هزینه های عملیاتی بسیار مهم است. در حالی که دستگا...Read More

-

Admin 19 Jan 2026

طراحی ساختاری ماشین فلوتاسیون نوع BF برای خرابی ناگهانی برق و مکانیزم های ضد ته نشینی

دستگاه فلوتاسیون نوع BF یک قطعه مهم از تجهیزات در کارخانه های فرآوری مواد معدنی است. در طول تولید واقعی، خاموشی های برنامه ریزی نشده ناشی از قطع...Read More

-

Admin 12 Jan 2026

برنامه نگهداری منظم و قطعات سایش مخزن مخلوط دوغاب نوع XB چیست؟

بازرسی منظم موتور و سیستم انتقال موتور جزء اصلی محرک است مخزن مخلوط دوغاب نوع XB . عملکرد طولانی مدت می تواند باعث گرم شدن بیش از حد، لرزش یا مشکلا...Read More

-

Admin 05 Jan 2026

شرایط عملیاتی مناسب برای مخزن مخلوط دوغاب نوع XB چیست؟

اختلاط دوغاب با ویسکوزیته بالا را مخزن مخلوط دوغاب نوع XB برای اختلاط مداوم و همگن سازی دوغاب با ویسکوزیته بالا ایده آل است. دوغاب هایی با محتوای ج...Read More

-

Admin 22 Dec 2025

رابطه بین ظرفیت پردازش تک واحدی تجهیزات فلوتاسیون نوع JJF و غلظت خمیر چیست؟

تجهیزات فلوتاسیون JJF یک دستگاه فلوتاسیون پرکاربرد در معدن مدرن است که برای جداسازی مواد معدنی فلزی و غیرفلزی مناسب است. ترکیب منحصربهفرد روتور-استاتو...Read More

-

Admin 15 Dec 2025

چه اقدامات حفاظتی ایمنی برای مخزن مخلوط عامل نوع XBY در شرایط فشار بالا یا دمای بالا وجود دارد

چالش های ایمنی در عملیات های پرفشار و دمای بالا این مخزن اختلاط عامل نوع XBY به طور گسترده ای در صنایع شیمیایی، دارویی، غذایی و صنایع شیمیایی خوب ا...Read More

-

Admin 08 Dec 2025

چه نوع سیستم آب بندی در مخزن مخلوط عامل نوع XBY استفاده می شود

اهمیت طراحی کارآمد آب بندی را مخزن اختلاط عامل نوع XBY به طور گسترده ای در صنایع شیمیایی، دارویی، غذایی و صنایع شیمیایی خوب استفاده می شود. سیستم آ...Read More

What material characteristics should be considered during the selection of ore feeding equipment?

Ore feeding equipment is one of the most important equipment in the production process of mining, metallurgy and related industries. It is responsible for accurately and stably transporting ore from the raw material stockpile area to the next processing step, such as crushing, screening, etc. During the selection process, how to reasonably select suitable feeding equipment is the key to ensuring production efficiency, reducing equipment loss and increasing output. Zhejiang Golden Machinery Factory, as a leading mining equipment manufacturer in China, has accumulated many years of experience in the field of mineral ore feeding equipment and can provide efficient and reliable feeding equipment according to the characteristics of different materials.

1. Ore particle size and distribution

The particle size of the ore directly affects the selection and operation efficiency of the mineral ore feeding equipment. Coarser ore may put greater pressure on the conveying system of the feeding equipment, while finer ore is prone to blockage, accumulation and other problems. Therefore, when selecting, it is necessary to determine the type of feeding equipment according to the particle size and particle size distribution of the ore. For example, if the ore particles are large and uneven, it may be necessary to select a vibrating feeder or grid screen equipment with strong conveying capacity.

When designing ore feeding equipment, Zhejiang Golden Machinery Factory takes into account the actual situation of ore particles and provides a variety of customized options to adapt to ores of different particle sizes, such as providing strong vibration equipment for coarse ores and high-precision screening and conveying equipment for fine ores.

2. Hardness of ore

The hardness of the ore is an important factor affecting the working stability and service life of the mineral ore feeding equipment. Ores with greater hardness (such as iron ore, copper ore, etc.) require the feeding equipment to have stronger wear resistance and higher load-bearing capacity. When selecting feeding equipment, it is necessary to evaluate the hardness of the ore and ensure that the material and structure of the equipment can withstand this high-intensity working environment. Too soft equipment may cause failure due to excessive wear in a short time, thereby affecting the stability of the production line.

Zhejiang Golden Machinery Factory's ore feeding equipment is made of high-strength, wear-resistant materials, which can effectively cope with ores with greater hardness. For example, for hard ores such as iron ore, Zhejiang Golden Machinery Factory uses steel with super wear resistance to enhance the service life and work efficiency of the equipment.

3. Humidity and viscosity of ore

The humidity and viscosity of ore are also key considerations in the selection process. Ores with high humidity are prone to agglomeration, which in turn hinders the normal operation of the equipment and may even cause equipment blockage. For ores with high water content, it is necessary to select mineral ore feeding equipment with better drainage function or anti-blocking design. For example, a vibrating feeder with self-cleaning function or equipment with strong vibration effect can effectively prevent wet ore from accumulating in the equipment and ensure continuous and stable feeding.

Zhejiang Golden Machinery Factory is well aware of this and has added a number of waterproof and anti-adhesion technologies when designing equipment. By optimizing the vibration frequency and device structure, the ore can flow smoothly even in a wet state, reducing the negative impact caused by the high humidity of the ore.

4. Density and specific gravity of ore

The density and specific gravity of ore have an important influence on the conveying capacity of feeding equipment. High-density ore has a high specific gravity and a heavier weight per unit volume, which puts higher requirements on the carrying capacity and power requirements of the equipment. For ores with higher density, it is necessary to select equipment with higher load capacity, and reasonably configure the motor power and power system to ensure that the equipment can still run smoothly under heavy load.

Zhejiang Golden Machinery Factory provides a variety of high-efficiency mineral ore feeding equipment according to the specific gravity characteristics of different ores to ensure that the equipment can run stably and efficiently when processing high-density ores to avoid overload or damage.

5. Corrosiveness of ores

Some ores, such as sulfur-containing ores and chlorine-containing ores, are highly corrosive, which places higher requirements on the material of the equipment. If this characteristic is not taken into account, long-term use will cause serious corrosion on the surface of the equipment, affecting the performance and service life of the equipment. Therefore, for corrosive ores, materials with strong corrosion resistance should be selected when selecting, and the equipment should be treated with anti-corrosion.

Zhejiang Golden Machinery Factory's ore feeding equipment uses high-quality stainless steel and corrosion-resistant materials. Especially for highly corrosive ores (such as some metallurgical ores), the company adds anti-corrosion coatings and special alloy materials to the equipment design to ensure the reliability of the equipment in long-term operation.

6. Ore flowability

Ore flowability directly affects the selection of mineral ore feeding equipment. If the ore particles are too coarse or irregular in shape, it may cause increased resistance during the transportation of materials, thus affecting the normal operation of the equipment. On the contrary, ores with regular shapes and uniform particle sizes are easy to flow smoothly and the equipment load is small.

Zhejiang Golden Machinery Factory optimizes the design of the equipment through advanced fluid mechanics simulation technology to ensure that even ores with poor flowability can be smoothly transported through the mineral ore feeding equipment, thereby avoiding problems such as ore accumulation and blockage, and ensuring the smooth progress of production.

7. Ore particle grading and impurities

Ore may contain impurities (such as mud, debris, etc.), which will affect the operating efficiency of the mineral ore feeding equipment. In particular, ores with more impurities will increase equipment wear and may even cause equipment blockage. Therefore, when selecting the model, it is necessary to evaluate the proportion of impurities in the ore and select the appropriate equipment based on this factor.

During the equipment design process of Zhejiang Golden Machinery Factory, the impurity composition in the ore has been optimized. Through an efficient screening and cleaning system, the equipment can effectively isolate impurities in the ore, reduce wear on the equipment, and thus improve the operating efficiency of the equipment.

What are the key factors affecting the efficiency of ore feeding equipment?

Ore feeding equipment is an important mechanical facility in the fields of mining, metallurgy, etc. Its main function is to evenly transport ore to the next process at a stable rate. Effective feeding equipment can not only improve production efficiency, but also reduce equipment wear, reduce energy consumption, and optimize the entire production process. Below we will analyze the key factors affecting the efficiency of ore feeding equipment from multiple angles.

1. Material properties of ore

The material properties of ore have a significant impact on the efficiency of feeding equipment. The physical properties of ore such as particle size, hardness, humidity and water content will directly determine the selection and working efficiency of feeding equipment. For example, ore with a high water content is easy to adhere to the inner wall of the equipment, causing equipment blockage or hindering normal transportation. Ores with higher hardness require more durable feeding equipment to cope with wear. Zhejiang Golden Machinery Factory fully considered the characteristics of different types of ores when designing and manufacturing feeding equipment, and developed equipment suitable for a variety of ores to ensure that the equipment can operate efficiently under different conditions.

2. Feeding rate and regulation

Feeding rate is a key factor affecting the efficiency of ore feeding equipment. Too high or too low feeding rate will lead to unstable production process, which will affect the overall efficiency. Too high feeding rate may cause material to be retained or blocked in the equipment, which will reduce the processing capacity of the equipment; while too low feeding rate will lead to insufficient load of the production line and reduce the overall output. Therefore, the reasonable feeding rate should be accurately adjusted according to the ore type, processing volume and process requirements.

Zhejiang Golden Machinery Factory's advantage in this regard lies in its advanced automatic control system, which can automatically adjust the feeding rate according to production needs to ensure uniform material flow and no waste of resources. Through precise control, production fluctuations caused by human operating errors can be avoided, thereby improving the operating efficiency of the equipment.

3. Equipment design and structure

The design and structure of the equipment directly affect its working efficiency. Ore feeding equipment needs to have high wear resistance and corrosion resistance, and be able to adapt to long-term operation under different working conditions. Zhejiang Golden Machinery Factory combines its many years of engineering experience and technological innovation to launch a variety of feeding equipment that meet different needs, including vibrating feeders, belt feeders, etc. These equipment not only have excellent material conveying performance, but also can effectively reduce wear and increase service life.

In addition, the streamlined design of the feeding equipment can also improve its conveying efficiency. Zhejiang Golden Machinery Factory uses advanced computational fluid dynamics (CFD) technology to optimize the structural design of the equipment, ensure the smooth flow of ore in the equipment, and reduce unnecessary energy loss.

4. Power system and transmission efficiency

The power system and transmission efficiency of ore feeding equipment are another important factor affecting the working efficiency of the equipment. The selection of the power system needs to be optimized according to the working load, feeding amount and working environment of the feeding equipment. An efficient transmission system can reduce energy loss and improve mechanical efficiency. Zhejiang Golden Machinery Factory's feeding equipment is equipped with efficient and stable motors and reducers, ensuring that the equipment can run smoothly under high load conditions and maintain high efficiency for a long time.

5. Uniformity of material delivery

The working efficiency of ore feeding equipment is closely related to the uniformity of material delivery. Uneven material delivery can cause load fluctuations in downstream equipment and even cause blockage or damage to the equipment. Therefore, the feeding equipment needs to have precise material distribution capabilities to ensure that the ore can enter the next process evenly and stably. Zhejiang Golden Machinery Factory's vibrating feeders and belt feeders both use precise vibration frequency control technology to ensure that the feeding amount and flow rate of the ore are optimally balanced.

6. Maintenance and care

The daily maintenance and care of the equipment is essential to maintain the efficient operation of ore feeding equipment. Regularly checking various parts of the equipment and replacing worn parts in time can effectively avoid equipment failures and improve production efficiency. Zhejiang Golden Machinery Factory widely uses modular design in its products to facilitate maintenance and replacement of parts, reduce equipment downtime, and improve overall work efficiency.

In addition, the company also provides customers with comprehensive equipment maintenance and technical support services to ensure the stable operation of the equipment throughout its life cycle and avoid production line stagnation due to equipment failure.

What are the common faults of ore feeding equipment? How to perform preventive maintenance

Ore feeding equipment plays a vital role in the mining, metallurgy, chemical and other industries. It not only ensures that the ore is stably and evenly transported to the subsequent processing equipment, but also directly affects the production efficiency and the normal operation of the equipment. However, in the long-term operation of ore feeding equipment, it is inevitable to encounter different types of faults, which may cause equipment downtime and affect the overall production progress. Therefore, understanding these common faults in advance and performing effective preventive maintenance is the key to improving equipment reliability and extending service life.

Common ore feeding equipment failures

Equipment blockage

Equipment blockage is one of the most common problems in ore feeding equipment. When the ore particles are too large, the humidity is too high or it contains a lot of impurities, it is easy to get blocked in the equipment. Especially for wet ore, the ore with strong viscosity may form lumps in the feeding trough, hindering the normal flow of materials.

Vibration system failure

Many ore feeding equipment uses vibrating feeders for material transportation, and vibration system failure is another common problem. Due to long-term use or improper maintenance, components such as vibration motors and vibrators may wear, loosen or have electrical failures, which may lead to a decrease in the performance of the vibration system, affect feeding efficiency, and even cause equipment shutdown.

Belt conveyor slippage and breakage

In equipment using belt feeders, belt conveyors are one of the most important components. Due to the large friction of ore, the belt will wear, age or break after long-term use. Especially when handling wet ore or ore containing impurities, the belt is prone to slippage or breakage, resulting in poor material transportation.

Power system failure

The power system of ore feeding equipment, including motors, reducers, etc., may cause the equipment to fail to start or operate normally if a failure occurs. Problems such as overload and overheating are often caused by insufficient motor power or damage to reducer components. Long-term neglect of these problems may cause the equipment to fail to work smoothly.

Uneven material distribution

An important task of ore feeding equipment is to evenly transport ore to the next process. When the equipment fails, it may cause uneven distribution of ore, which in turn affects the workload of subsequent processing equipment and even causes blockage or overload operation.

Excessive wear of equipment

Ore is highly abrasive during transportation, and long-term operation will cause wear of equipment, especially high-friction parts such as vibrating devices, belt conveyor systems and metal parts. Once these parts are severely worn, it will directly affect the service life and operating stability of the equipment.

Preventive maintenance of ore feeding equipment

Preventive maintenance is an effective means to improve the reliability and extend the service life of ore feeding equipment. The following are some key preventive maintenance measures:

Regular inspection and cleaning

Regular inspection is the basis for ensuring the normal operation of equipment. Zhejiang Golden Machinery Factory emphasizes that during the operation of the equipment, the working status of each component, including motors, reducers, vibrators, belts, material troughs, etc., should be checked regularly, and dust and impurities should be cleaned in time to ensure the smoothness and stability of each component of the equipment. Especially for wet ores or ores with more impurities, the cleaning frequency should be increased to prevent blockage and equipment overload.

Lubrication and sealing management

Many moving parts in ore feeding equipment, such as vibrators, motors, reducers, etc., need to be kept in good lubrication. Regularly replacing lubricating oil and checking the integrity of seals are the key to reducing wear and improving equipment stability. In addition, for equipment that is exposed to high humidity and high temperature for a long time, the sealing system should be checked regularly to prevent moisture or other harmful substances from entering the equipment.

Adjustment and calibration

After long-term use, some parameters of the equipment may deviate, such as vibration frequency, feed amount, conveying speed, etc. Regular adjustment and calibration can not only improve the operating efficiency of the equipment, but also prevent equipment failure caused by mismatch of working parameters. Zhejiang Golden Machinery Factory provides professional commissioning services and provides customers with real-time data monitoring and analysis of equipment operation to ensure that the equipment operates in the best condition.

Timely replacement of worn parts

For high-friction parts in ore feeding equipment (such as vibration motors, belt conveyors, etc.), they need to be replaced in time according to the wear conditions. Timely replacement of worn parts can not only avoid equipment failure, but also improve the efficiency and stability of the equipment. The equipment design of Zhejiang Golden Machinery Factory adopts a modular structure, which is convenient for quick replacement and maintenance, thereby reducing downtime and ensuring long-term stable operation of the equipment.

Load monitoring and overload protection

Regularly monitoring the equipment load and equipping the equipment with an overload protection system can effectively prevent equipment failure due to overload. Through the intelligent control system, Zhejiang Golden Machinery Factory's ore feeding equipment can monitor important data such as equipment load, vibration frequency, current, etc. in real time, and automatically adjust and protect to prevent equipment damage.

Training operators

Operators are a key link in the maintenance and management of ore feeding equipment. Zhejiang Golden Machinery Factory provides customers with professional operation and maintenance training to help operators understand the basic working principles of the equipment, master the troubleshooting methods of common faults, and ensure the safety and stability of equipment operation.

Environmental control

The operating environment of ore feeding equipment has a direct impact on its life. Equipment should be avoided from being exposed to high humidity, high temperature or highly corrosive environments. Regularly check the working environment of the equipment to avoid ore dust accumulation or other adverse factors affecting the normal operation of the equipment.

EN

EN